We talk DATUM tech with DIGIT BIKES' Tim Lane

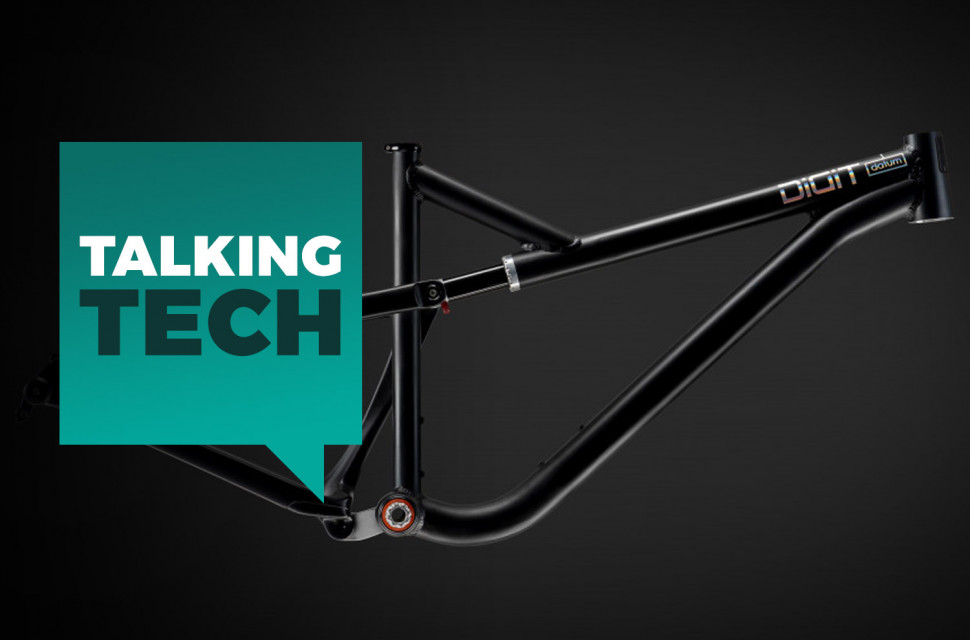

Back in September of 2021, we caught wind of a rather interesting and unique bike from a brand called DIGIT BIKES. That bike was the DATUM and what made it so eye-catching was that it uses an Interger Strut instead of a conventional air shock, which is built directly into the frame. We caught up with DIGIT BIKES' founder, Tim Lane to uncover more about this new bike that's received full funding on Kickstarter.

- Talking Tech: Liam's 2022 predictions - What new kit might we see this year?

- We talk with Starling Cycles about thermoplastic carbon

- We get hands-on with the new PNW Loam pedals

The Datum is clearly quite a radical design, what inspired you to go down the integrated suspension route?

In a word, simplicity.

It has taken decades for mountain bike suspension to reach the high level of performance that we're familiar with today. My goal was to make a damned good bike, with suspension performance equal to or exceeding the very best out there, and then to improve on that by removing redundant components to improve stiffness and reliability. I got lucky that this also reduces weight, permits lots of water bottle carriage, and accepts loooong dropper posts even on small frames.

The main challenges I see with current mountain bikes are over-complexity and under-reliability. These are closely related – there are bikes on the market with rear suspensions that use 22 bearings and 14 pivot axles, each offering an opportunity for mechanical lash, stripped threads, dirt ingress, misalignment, being too loose, being too tight, breaking, seizing, wearing, being heavy, etc… The Analog system has less of all of that.

The shock design is something we've never seen before, has it been designed in collaboration with any other brand?

The Integer Strut is 100% Digit designed and manufactured.

To put that decision in the context of what is currently available in the market, as well as our goals for producing the Analog suspension system in the first place, you have to look at the corner that major shock and frame manufacturers have backed themselves into. Basically, they produce shocks that have to fit in a relatively small space, that can work at high leverage ratios, and that can be affordably tuned or modified to meet the criteria of any number of manufacturers’ designs. The shocks they have produced, designed to those parameters, are both remarkable, and remarkably complex. Again, I prefer simplicity.

Having experience of both frames and shocks, we have the freedom to design a strut exclusively matched to our suspension design - we don’t have to compromise or complicate our design to make it work across other manufacturers’ platforms. The Analog suspension design itself eliminates most of the size/packaging constraints* placed on shocks/struts for other bikes. And our suspension system operates with a lower leverage ratio. All of this has enabled us to step away from what is typical in the suspension market, and design something that matches our goals for making bikes in the first place: excellent performance; reduced complication; increased reliability.

*This image shows Integer compared to a conventional shock to illustrate how not adhering to the convention packaging limitations allows more room for oil/air/bushings/etc...

Do you have any plans to introduce this suspension platform to something other than a trail bike?

Yes, I intend to build a full line of bikes.

Interestingly, one definition of 'Datum' is an engineering term for 'reference', it's my reference design, from which subsequent models will be measured.

Have you tested the frame's stiffness and how does it stack up against frames with traditionally mounted shocks?

I've not lab tested the frame's stiffness yet because I've been working with pre-production prototypes, any result would only relate to the handful of prototypes, not to something available for sale. In this video (click here) I discuss the prototype which was ridden in the reviews, and how many aspects are not of production quality. The production bikes are much better in every way.

With that said, when riding the prototypes the frame stiffness is very apparent when compared to other (very well respected) bikes I have tested against. The gains are captured by reducing the number of pivots, and using a strut with increased shaft diameter and bushing overlap compared to market norms.

Have you done any testing with carbon?

Not yet with relation to Digit. I've made plenty of carbon bikes throughout my career, but aluminum feels right in the context of my overall goals for a bike - dependable, uncomplicated performance, efficient design, manufactured locally, recyclable.

Though low weight was not my primary goal - the reduced parts count, and the closed triangle construction of both the front and rear triangles both contribute to comparable (or lighter) weight than carbon frames or similar intent.

What's the expected service life of the shock and how do you go about servicing it? Is it something you can take to a service centre to have refreshed?

Because of the higher oil volume, lower leverage (i.e. lower forces), and increased strut diameter, we anticipate longer than 'normal' service life for the strut. We have not yet set a recommended number of hours, though.

Any competent mechanic or suspension service center will be able to completely work on our strut without special tools or nitrogen charge equipment. We'll also offer service manuals and likely a mail in service option.

There's a background video here showing the general assembly order, and a photo here showing all the required tools.

The main wiper seal can be re-lubed (akin to an air-can or lower-leg service) without taking the shock apart or removing it from the bike.

Can you outline the benefits of the Datum's design?

In short? High performance, with increased durability, reliability, and serviceability have been our driving goals since beginning the design process.

When can consumers expect to purchase and receive their Datum frames?

We're accepting orders now at DigitBikes/com/datum.

Consumers who placed initial pre-orders with us will receive bikes in early-to-mid spring of this year. Orders placed today, by late spring.

Is there a plan to offer full builds?

Full builds will probably be a next step for us, yes. If the supply chain crunch ever lets up!

Building only frames at this time allows us to equip eager riders when their frames are ready - if we were selling complete bikes we could have almost complete bikes, with everything except for a chain and cassette, which we'd be unable to ship until chains arrive (which would add many months).

Will we see bikes available in the UK?

Yes. We are currently in discussions with distribution partners and suspension service providers to be sure that our UK customers will be able to receive the same level of service as our US customers. I'm a Brit and worked in the UK as suspension support tech, so I have some experience and reliable contacts in this area.

What's next for Digit Bikes?

New models for sure. But first, as always, another mug of tea.